“In 2025, construction companies are revising their approach to forming a fleet of equipment. Instead of a large number of specialized machines, universal solutions are increasingly being chosen, which are able to perform several types of work and reduce maintenance costs. This is not only an optimization of the budget, but also an increase in mobility – the equipment is less idle, moves between objects faster and is used to the full. Correctly selected […]”, — write: businessua.com.ua

In 2025, construction companies are revising their approach to forming a fleet of equipment. Instead of a large number of specialized machines, universal solutions are increasingly being chosen, which are able to perform several types of work and reduce maintenance costs. This is not only an optimization of the budget, but also an increase in mobility – the equipment is less idle, moves between objects faster and is used to the full.

Properly selected universal equipment allows you to reduce costs for service, fuel, movement and storage, as well as minimize downtime. Instead of maintaining a fleet of 5-7 units of specialized equipment, the company can effectively work on 2-3 universal machines.

Why businesses are switching to universal machines Modern construction projects require quick response and maximum efficiency. Companies are increasingly abandoning highly specialized equipment, which is difficult to pay off, and are betting on multifunctional solutions. That is why enterprises choosing universal solutions consider in most cases backhoe loaders https://tadgroup.com.ua/product-category/katalog/tech-ekskavatory-navantazhuvachi/type-nova-tehnika/ — equipment offered by TAD Construction Group Ukraine. This allows you to replace several individual units, optimize fuel and service costs, and reduce logistics costs.

The main reasons for such a transition:

- reduction of maintenance and repair costs;

- less need for a large fleet;

- quick payback due to constant workload;

- the possibility of replacing several machines with one universal model.

As a result, the company gets a more flexible approach to tasks and reduces dependence on renting equipment for one-off jobs.

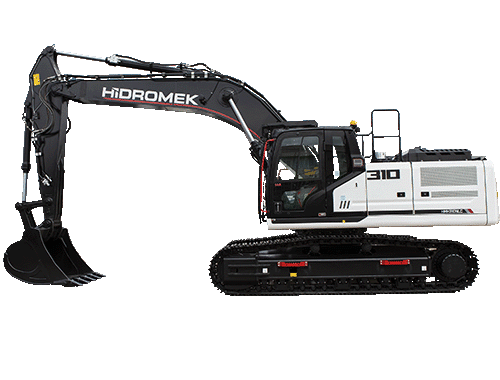

A technique that actually replaces several units Some types of machines demonstrate particularly high efficiency in combined tasks. In particular, in 2025, construction companies will most often repurpose the park into the following categories:

This is one of the most versatile types of equipment on the market today. One machine is capable of digging, planning, loading, moving loose materials and light demolition work. Thanks to the attached equipment, the backhoe loader can completely replace a skid steer loader, a small excavator and a front loader within the framework of one object.

Versatile in work with lifting loads, pallet materials and moving equipment. They can often replace the faucet at small facilities.

Due to their compactness and low fuel consumption, they are suitable for small trenches, installation of communications, landscaping. Full-size excavators are often replaced where there is no space to maneuver.

The role of the backhoe loader in optimizing the budget The backhoe loader is a key tool for companies looking to downsize without sacrificing productivity. It performs up to 70% of typical construction tasks, so it is suitable for both the private sector and industrial projects.

Advantages:

- one operator instead of two or three;

- reduction of fuel costs;

- no downtime between tasks;

- the opportunity to work in urban conditions and on industrial sites.

When one machine can do the work of three, the business receives net savings at all stages.

How to choose the right equipment for reducing the fleet In order for the optimization to be economically justified, several key factors should be taken into account:

- type of work that is performed most often;

- the number of parallel objects;

- the need for mobility and quick transfer of equipment;

- access to service and speed of repair;

- the possibility of using additional attachments.

Universal machines make sense where the objects are diverse, and the equipment works in different modes during one cycle.

Practical conclusions A rational approach to the formation of the vehicle fleet in 2025 is not in the quantity of equipment, but in its functionality. Companies switching to universal machines get better returns, faster start-ups and lower operating costs. The backhoe loader remains the most balanced solution among all universal models, able to replace several pieces of equipment at once without loss of productivity.

Please wait…