“

Dmitry Dzhugalik Author of news on Mezha.media. I write about what I actively admire, namely technology, games and cinema.

Vulcan is not the first industrial robot of Amazon to perform tasks for lifting and transporting goods in warehouses. Previously, the company had already used cars with visual systems and suckers to move goods, as well as robots that carry trolleys with products. However, due to the ability to tactile feedback, Vulcan opens up new prospects for warehouse operations.

“A typical robot is” silent and stupid “,” says Aaron Parness, director Aaron Parnes. He not only sees the world, he feels him that gives him opportunities that have been impossible for Amazon robots so far. ”

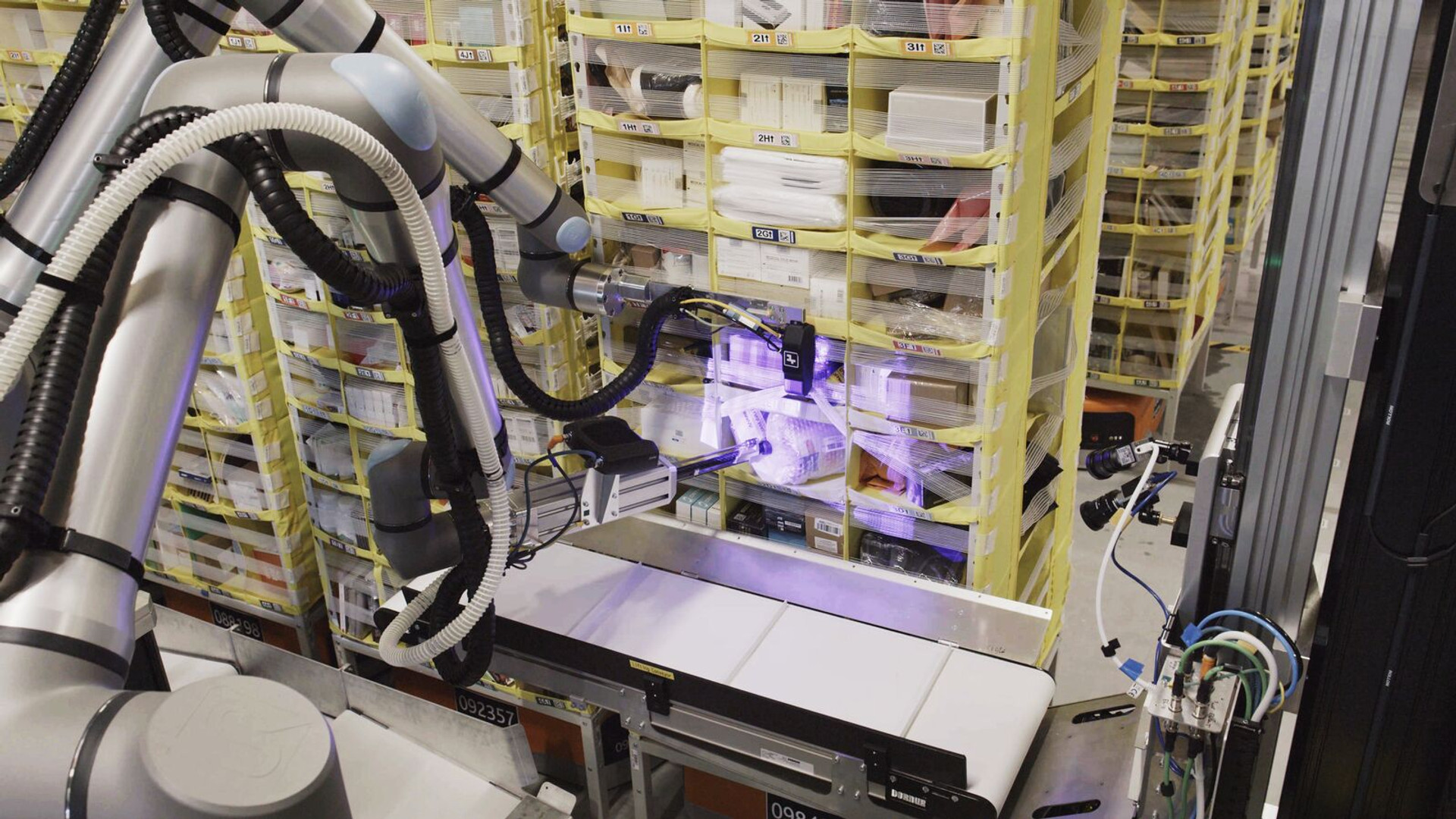

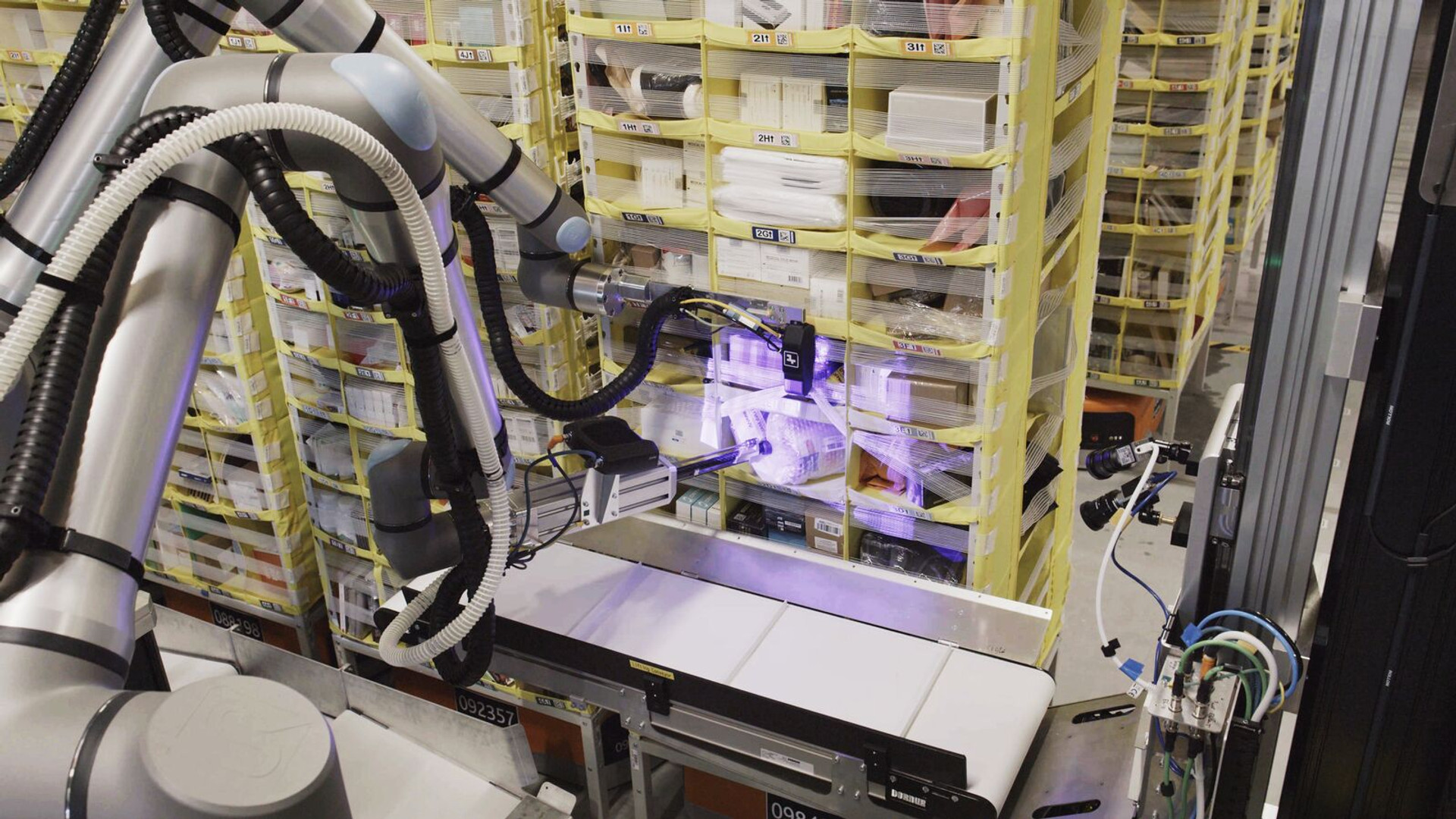

In Amazon sorting centers, the products are stored in capsules covered with fabric, which are divided into small compartments. Each contains up to ten units of goods. Due to the limited space, placement or removal of objects, it was a difficult task for traditional robots that lack human agility. However, Vulcan, thanks to tactile feedback, is able to easily control objects in tight compartments, effectively optimizing the space.

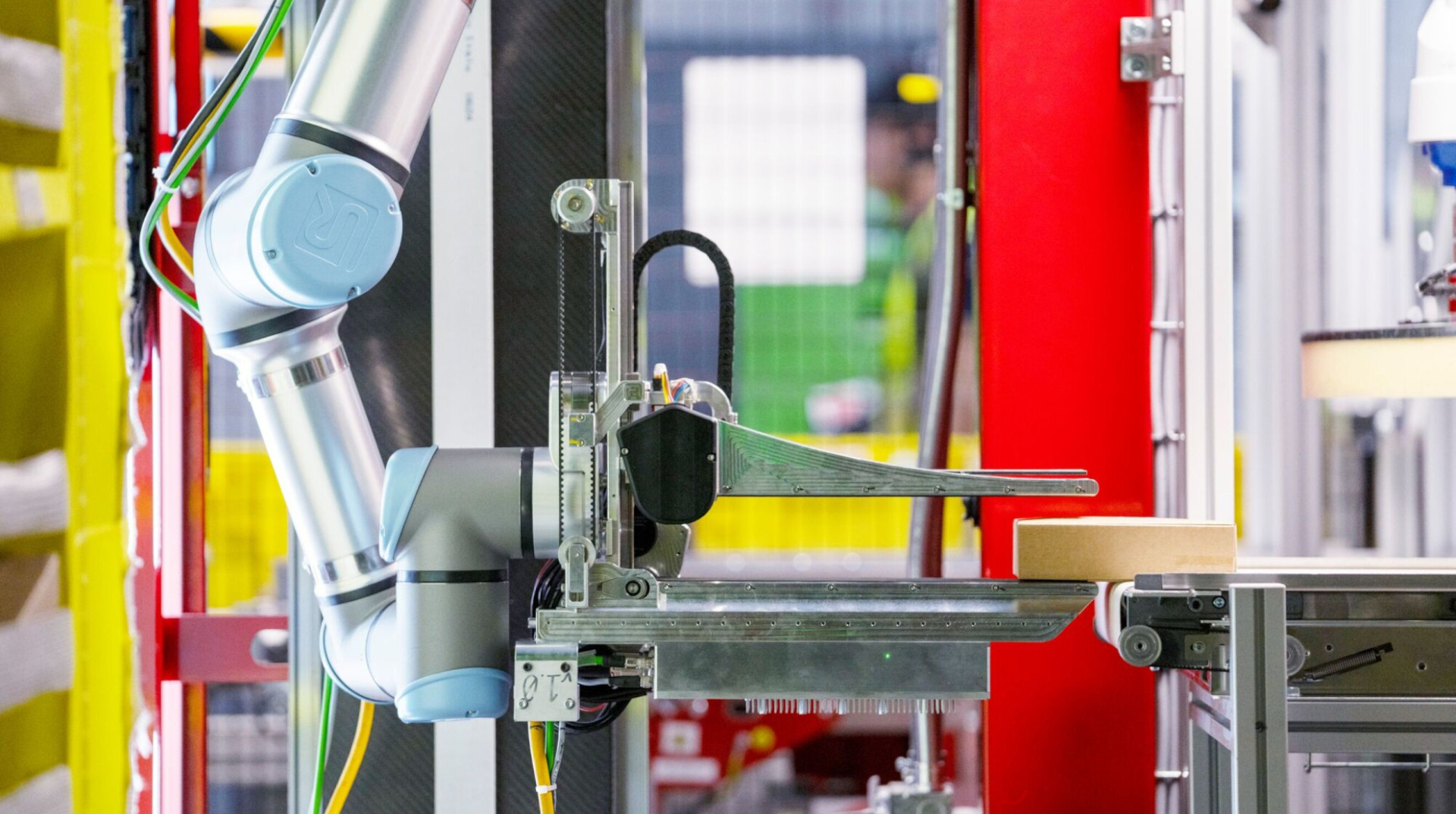

As Amazon explains, Vulcan has a “tool at the end of the hand”, which “resembles a line attached to a hair strain” paired with feedback sensors that tell him how much he pushes or holds the product. This may result in the robot below the point of force at which the inventory is at risk of damaging.

Vulcan is already being tested in US and Germany sorting centers. There the task of the work is to complete and put goods in the upper rows of warehouses. These containers are located at an altitude of about 2.4 meters, which is a threat to workers who need to get to them on the ladder. In total, the robot can lift and move about 75% of all items in warehouses and do so at the speed of efficient workers.

Amazon also notes that in addition to Vulcan, the company’s warehouses have more than 750 thousand different robots that help with the performance of various tasks, such as moving heavy parcels by warehouse or sorting. The new work is planned to be actively introduced in Europe and the US for the next few years.

”, – WRITE: mezha.media

Dmitry Dzhugalik Author of news on Mezha.media. I write about what I actively admire, namely technology, games and cinema.

Vulcan is not the first industrial robot of Amazon to perform tasks for lifting and transporting goods in warehouses. Previously, the company had already used cars with visual systems and suckers to move goods, as well as robots that carry trolleys with products. However, due to the ability to tactile feedback, Vulcan opens up new prospects for warehouse operations.

“A typical robot is” silent and stupid “,” says Aaron Parness, director Aaron Parnes. He not only sees the world, he feels him that gives him opportunities that have been impossible for Amazon robots so far. ”

In Amazon sorting centers, the products are stored in capsules covered with fabric, which are divided into small compartments. Each contains up to ten units of goods. Due to the limited space, placement or removal of objects, it was a difficult task for traditional robots that lack human agility. However, Vulcan, thanks to tactile feedback, is able to easily control objects in tight compartments, effectively optimizing the space.

As Amazon explains, Vulcan has a “tool at the end of the hand”, which “resembles a line attached to a hair strain” paired with feedback sensors that tell him how much he pushes or holds the product. This may result in the robot below the point of force at which the inventory is at risk of damaging.

Vulcan is already being tested in US and Germany sorting centers. There the task of the work is to complete and put goods in the upper rows of warehouses. These containers are located at an altitude of about 2.4 meters, which is a threat to workers who need to get to them on the ladder. In total, the robot can lift and move about 75% of all items in warehouses and do so at the speed of efficient workers.

Amazon also notes that in addition to Vulcan, the company’s warehouses have more than 750 thousand different robots that help with the performance of various tasks, such as moving heavy parcels by warehouse or sorting. The new work is planned to be actively introduced in Europe and the US for the next few years.